The EV industry is constantly evolving to make electrified technology more sustainable and attainable. Aside from Nissan’s initiative of building a factory dedicated to the next generation of EV batteries, the Japanese automaker has revealed a new approach to electrified powertrain development.

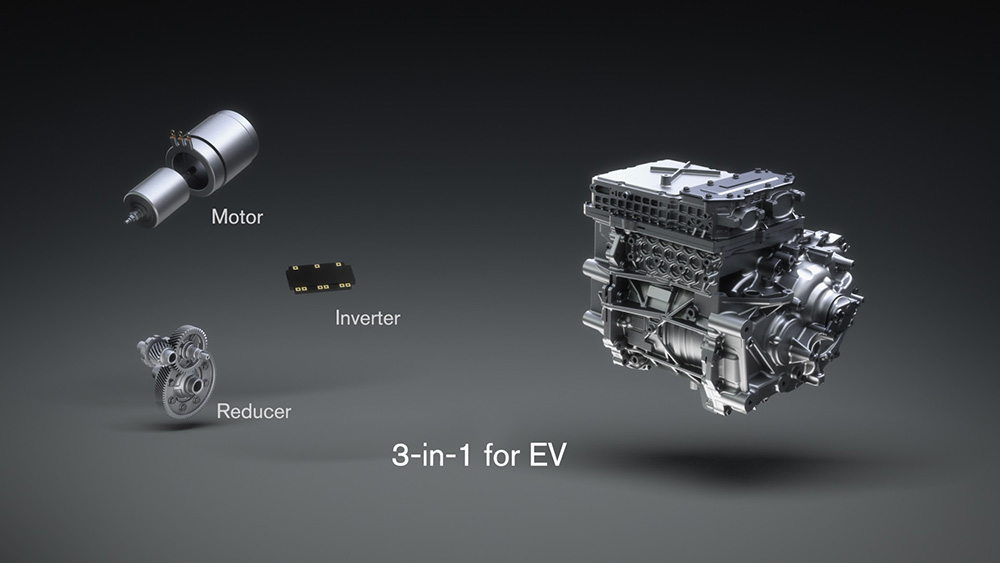

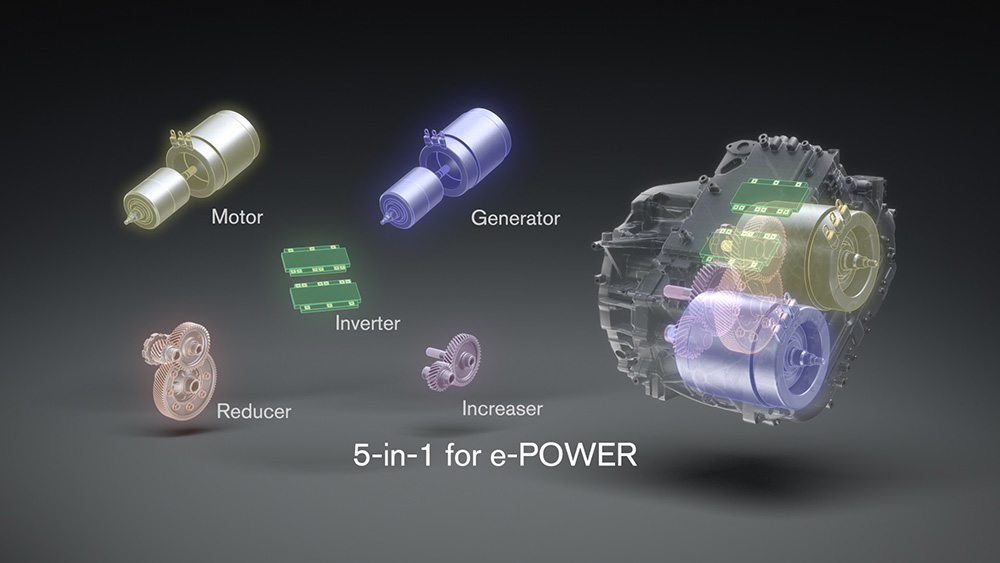

Dubbed X-in-1, the initiative is aimed at reducing development and manufacturing costs by sharing and modularizing EV components. This will eventually make Nissan’s electrified offerings (both e-Power and EV products) more competitive in the quickly expanding e-mobility segment.

Nissan has developed a 3-in-1 prototype for EVs, which covers the modularizing of the motor, the inverter, and the reducer. On the e-Power end, the brand cooked up a 5-in-1 prototype, incorporating the generator and the increaser.

To sum up the benefits of the X-in-1 electrified powertrain development, the new approach is anticipated to reduce production costs by 30% compared to 2019 with the goal of leveling e-Power vehicle pricing with that of ICE vehicles by 2026. Furthermore, X-in-1 will improve driving performance while minimizing noise and vibrations as vehicle weight and size are reduced.

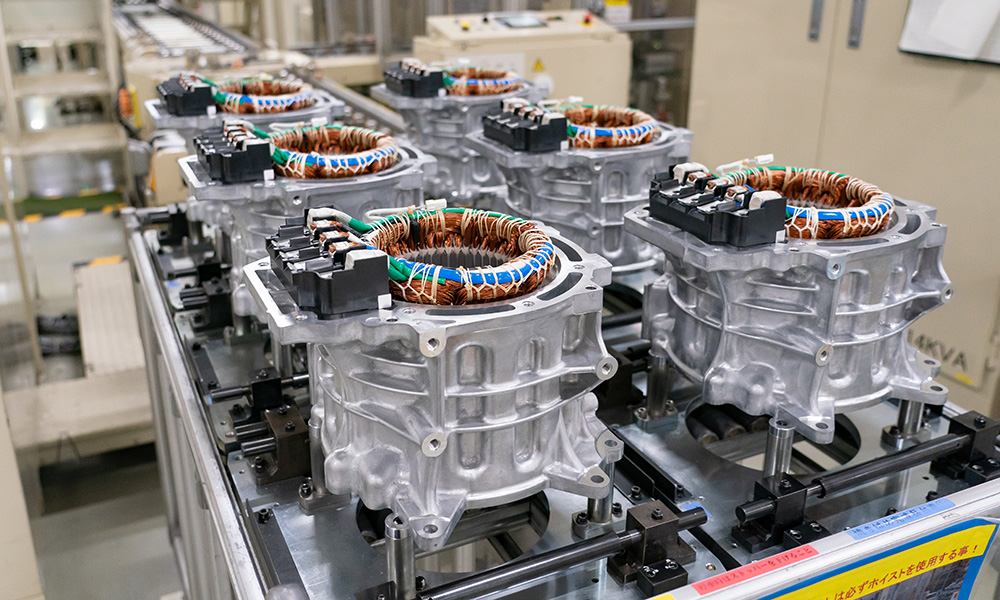

In addition, adopting a new motor that reduces the use of rare-earth elements down to 1% or less of magnet weight is a significant plus. All in all, sharing control technology and core components delivers an enjoyable driving and ownership experience that Nissan electrified vehicles are known for.

Just over a decade ago, Nissan was the first automaker to mass-market an EV through the Leaf; in 2016, it introduced its unique e-Power technology. With the brand’s long-term vision—Nissan Ambition 2030—the company aims to beef up its product menu with 27 new electrified models (which include 19 EVs) by the fiscal year 2030.

The X-in-1 initiative is another relevant step in painting Nissan’s big picture of an electrified future by strategically answering the mobility needs of each market it covers, ours included.

0 Comments