In the early 2000s, before Bonifacio Global City became a hubbub of condos, offices, and retail spaces, it was simply called “The Fort.” Near the center of the vast area was the “oval,” a paved roundabout some 800m in circumference where, every morning, cyclists all over the metro came to do dozens of laps before heading off to work. On Sundays, the local club would hold informal scratch races called “bente-bente,” where you paid P20 to join. The top three to finish the race split the pot. It was a place where noobs like myself at the time could meet and ride with aspiring pros and coaches, and perhaps learn a thing or two about suffering on two wheels.

It was during there and during those days that I first met Edward Perlas, also fairly new to cycling then and just as enthusiastic about the latest news in the world of cycling. In those days, we raced with whatever bikes we could afford—mostly secondhand frames, wheels, and components—while dreaming about $4,000 carbon-fiber racing wheels. Edward was fascinated with the art of wheel building even then, and so began a hobby that would eventually turn into one of the best-known brands in Philippine cycling: Carbon Nation Cycling.

“It all started from the time when we raced before, way back in 2003,” says Edward. “Hindi pa uso mga complete wheelset. Dati kasi, bibili ka ng rims, tapos hubs, then ipapabuo mo sa shop. Then may break-in period, and after that swerte mo kung mag-hold up yung wheels. Naalala ko nun, si Mang Nestor ang pinupuntahan ko pa sa Tryon Bike Shop. So, nagpapaturo ako sa kanya para hindi ko na kailangan pumunta pa ng Makati kasi taga-Pasig ako.”

After many years of research and practice, Edward finally got the hang of it, and was now confident in his skills as a wheel builder. But then a fateful trip to China let him meet a supplier of carbon-fiber rims and parts, which got him thinking. “I tried it. Nagbuo ako dito, and six months later nag-decide ako na magbenta na. Ang nag-push sa akin na gawin ito was yung mga kaibigan ko, kasi maganda naman, and why not try and sell it here, ‘di ba? That was 2011.”

At the time, Ed was happy to sell two wheelsets in a month, but he realized he could do more.

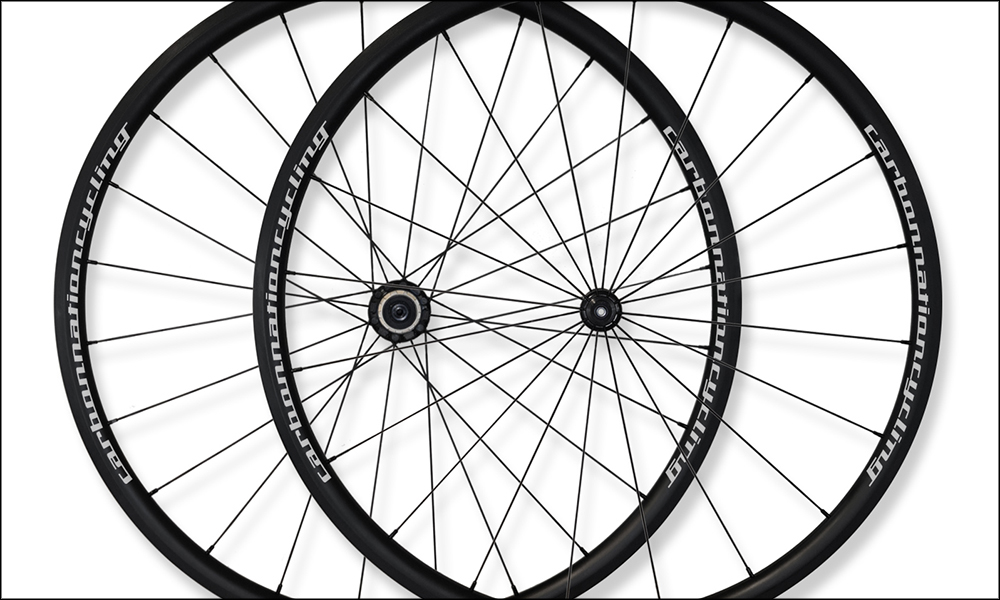

“Wala pa akong brand nuon, generic pa lang kasi nahihiya pa ako na sabihin na ako yung nagbuo. Kasi dito sa Pilipinas, branded agad ang hinahanap, and when you tell people na ‘ako ang gumawa niyan,’ parang you have to prove na maganda talaga iyan. Eventually, I decided to make my own brand, which was Carbon Nation Cycling in 2013, and to tell people that it was really hand-built in Manila.”

Malcolm Gladwell famously wrote in Outliers: The Story of Success that for anyone to achieve an expert level in any skill, the magic number is 10,000 hours of practice. 10,000 hours to perfect your free throw, 10,000 hours to become an expert shooter, and 10,000 hours to even be considered a pro-level athlete.

In Edward’s case, he’s quite proud of the fact that CNC sold its 12,000th wheelset at the end of 2021 (he started in 2013). With the average wheelset taking around 2.5 hours to build, that’s 30,000 hours of labor put into his craft—something you can’t get on YouTube or even in a vocational school.

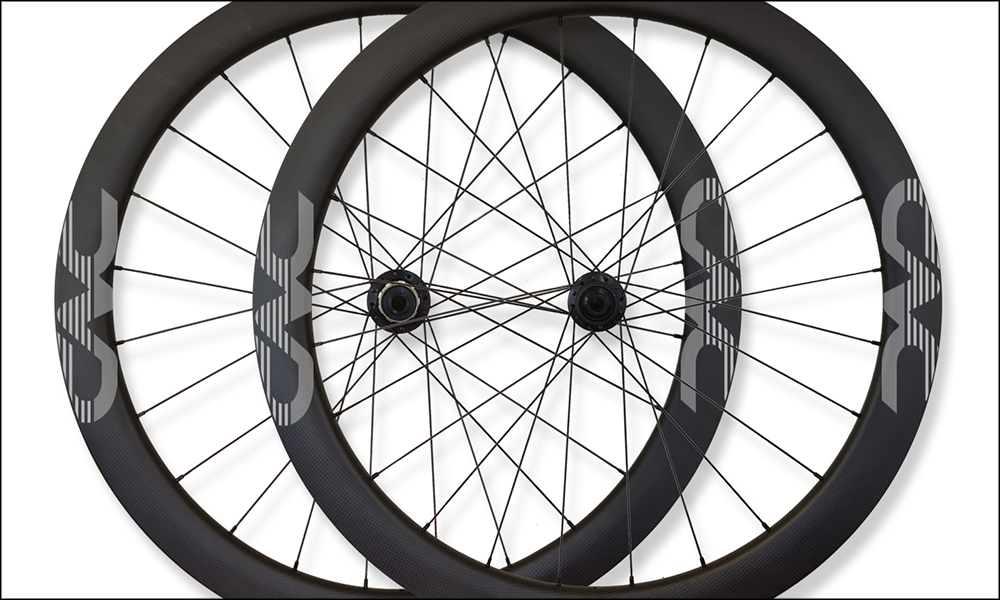

The fruit of all this labor is a wide array of carbon racing wheels that any competitive cyclist would be happy to ride. And with American- and European-branded wheelsets ringing in at anywhere from P80,000 to P200,000 (or even higher), CNC comes in reasonably priced in the P25,000 to P35,000 range, along with a one-year warranty. Customers can also specify rim depth, width, lacing, and hubs from the healthy menu of options on Edward’s website. As an added service, he also offers carbon frame repair, giving new life to a material that’s often thought to be irreparable compared to metal frames.

The business of wheel building has been good to Edward, so much so that it’s enabled him to afford another passion: motorcycles. At the height of the pandemic, cyclists having no races to join and needing some retail therapy placed numerous orders for CNC wheelsets, a demand Edward was only too happy to address. But the stress of dealing with supply chain issues as well as order deadlines finally pushed him to go ahead with a long-burning interest in motorcycles.

“Matagal ko nang gusto mag-motor,” he says. “Ito lang nung pandemic, I bit the bullet and said I’d try it out. If I liked it, then I’d keep it. If not, I could always sell it. Nagkataon lang na I had a friend who had a Royal Enfield Classic, and he decided to sell it! He gave it to me at a good price, so I tried it out first in the subdivision, and I enjoyed it. Kaso nabitin ako sa bilis, so I decided a month after to get a Ducati Scrambler.”

So, on days when he’s not on a training ride, he’ll take either of the two motorcycles for an easy morning ride in the hills of Tanay. Not an aggressive rider by his own admission, he does it to relax and de-stress from the pressures of running a business.

One major change that bike shops and suppliers have had to deal with in the past two years has been the rapid shift to disc brakes in the road bike category. As big brands have continued to push disc brake-only bikes while gradually phasing out rim brake frames, CNC has seen a big shift in demand toward disc wheels. Quite often, a customer will buy a complete bike from the shop with aluminum disc wheels. As “upgradititis” comes around, the first big upgrade is for a lighter and stiffer carbon wheelset, and it’s hard to beat CNC’s value-for-money proposition.

As Edward shares: “Before the pandemic, our market for disc wheels had been around 20% of total sales. Now, rim brake wheelsets only account for 20% of our sales. But it’s highly unlikely that rim wheelsets will go away, because it’s a legacy wheelset, and not everybody upgrades to disc. Even if manufacturers are focusing on building disc frames, they’re still making rim brake frames.”

So if you’ve decided to stick with your rim brake frame, no worries about compatible upgrades because CNC will continue to make wheels for that. Even if you never see Edward riding around on his bikes, chances are you’ve seen his work if you’ve hung around the local peloton. From equipping new enthusiasts to pro cyclists, Edward is proud to say that his work is something all Filipinos can be proud of.

0 Comments