If you’ve ever gone up a mountain road, chances are you’ve seen heavily laden trucks lumbering along at just above walking pace. That’s because even with the advent of more efficient turbochargers and common-rail injection (plus the possibility that most of these rigs may be overloaded), the laws of physics dictate that air density decreases as altitude increases. This means that there is lesser oxygen for engines to breathe the higher they go.

Frankly, this affects every single motor that traverses hill climbs like Baguio or Tagaytay. But while your SUV probably tips the scales at around 2,500kg, trucks weigh at least 20 metric tons. And that’s where the performance degradation becomes so much more significant. Combine that with the struggle of going against the pull of gravity and you’ve got a vehicle that will surely take forever to reach the summit.

And that brings us to the idea of using electric power to increase the performance potential of large commercial vehicles. Recently, a Peterbilt 579EV became the first Class 8 truck to make it up to the 14,115ft (4,300m) top of Pikes Peak in Colorado. And as far as big rigs go, Class 8 is the heaviest in the US with a gross vehicle weight of at least 15,000kg, so the Peterbilt’s 670hp electric powertrain does pack quite a punch.

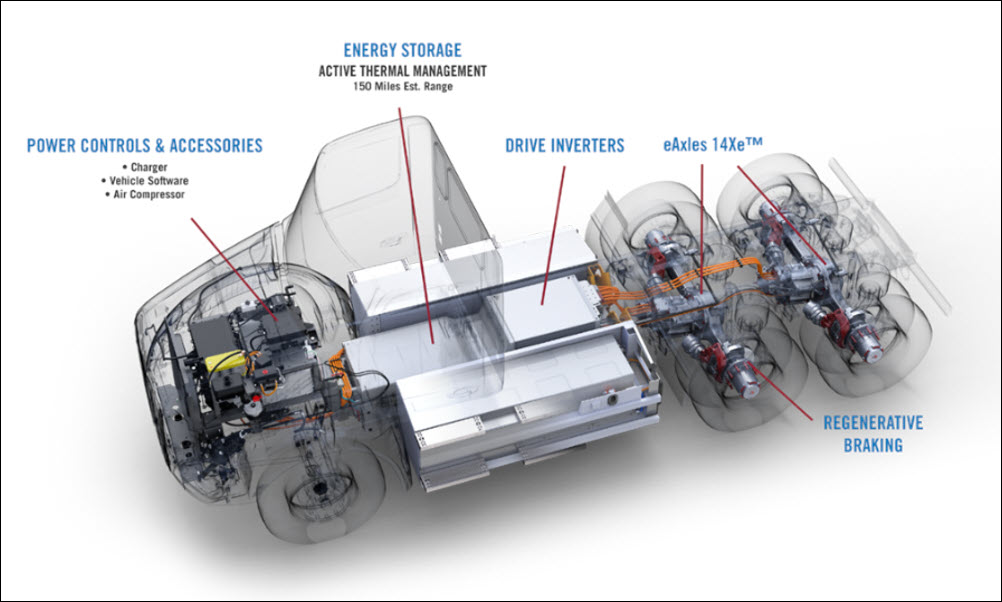

Since electric motors work irrespective of air density, they can technically produce the same amount of power no matter the altitude. Also, these powerplants deliver maximum torque at zero rpm, so hill starts should be easier to execute than in a traditional diesel rig. In addition, most electric vehicles have regenerative braking that diverts the kinetic energy from freewheeling to charging the battery, which, in theory, behaves like engine-braking when going downhill. Finally, there’s that added benefit of not having any harmful emissions, which, on top of the performance improvements, is reason enough to smile.

Of course, one of the biggest drawbacks of electric power is endurance. Batteries are not as energy-dense as diesel fuel, so driving range on a single charge is generally less than that of a comparable truck with a piston engine. And then, there are the not-so-small issues of charging stations and charge times. The 579EV, for example, takes 3.5 hours to be fully charged and can manage just 241km at best from a juiced-up battery.

But just like how internal-combustion engines have become more efficient over the years, there will come a time when electric powertrains will be just as frugal on battery charge and charging times will be significantly reduced. And with battery-powered cars and buses becoming more and more commonplace, we suspect that it won’t be very long before electric trucks become similarly mainstream.

0 Comments